|

|

|||||||||||||||||||||||||||||||||||||

|

Home | Products | Material Specifications | Machining Services | Additional Products | Application Support Ordering Information | Contact Strongbar | Contact RotoPrecision | Press Releases

Material Specifications

Material Available

Sourced from a number of world-class suppliers to ensure

maximum quality and availability, Strongbar offers a

wide range of case-hardened linear shafting and guide

bars from generous stock. We typically stock, grind and

machine a broad range of both imperial and metric

high-carbon alloy steels and stainless steels in a range

of tolerances.

Carbon steels to B.S. 070M55 (solid and hollow/tube)

Should you require custom materials that vary in, for example, chemical

composition, we are pleased to offer the ability to

source and to machine almost all types of material. Available diameters and tolerances

3mm to 80mm Ψ 3/16" to 3" Ψ and specials up to 6" Ψ Metric tolerances h6 and h7 Imperial tolerances Class L or S Chrome and plated shafting to h6, Class L and S tolerances

Special tolerances available to order

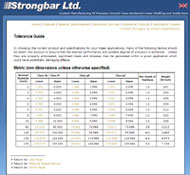

View a Shafting Tolerance

Guide:

Click here

Hardness and Depth of Hardness

As one of the more critical elements in shafting

selection, the appropriate choice of material hardness

and the depth of hardness (for case hardened material)

will ensure an appropriate resistance to wear, higher

strength, and increased load-carrying capacity. The

result is an improved resistance against deformation,

bending, and rotational fatigue, as well as the ability

to maintain critical dimensions over a longer period of

time which will extend the life of your applications. Rockwell 50-55C (Stainless Steels and 440C) Rockwell 60-65C (Solid and hollow/tube)

Surface Finish

Surface finish is a key variable affecting the

smoothness of travel, the load level capacity,

resistance due to friction, and the overall life of a

shaft. Strongbar is pleased to offer surface finishes

better than industry standards whenever your

circumstances require it.

Standard finishes: ground and polished to 8-12 CLA Length Tolerance

Stock is generally supplied with a standard finished

length tolerance of ±1/32 for shafts up to 1-1/4

diameter, and ±1/16 for shafts over 1-1/4 diameter.

For metric, we offer a standard finished length tolerance of ±.01mm. Closer tolerances are available

upon request. Standard Shaft and Extra-Long Shafts

Standard shaft lengths are stocked in 3m (188") lengths.

Extra-long shafts are

available by special order to provide single imperial lengths up to 300

and single metric lengths up to 7.6m.

In addition, we are capable of providing multi-piece

shafts up to virtually unlimited lengths through shaft

coupling and end-machining whereby a series of shafts

are joined end-to-end. Please call if you requires to inquire about

these options. Straightness Tolerance

Another key element to ensure precision in a given

application is the overall straightness of a linear

shaft. With a straighter shaft, cutting tools, gauges

and positioning tables will be able to achieve a higher

degree of accuracy and precision than may otherwise be

achievable. For manufacturers, starting with a

straighter shaft will translate into less work-around

and variance compensation in the later stages of both

the design and construction process, thereby increasing

overall turnaround time and improving the final quality

of the end products. Chamfering

Standard chamfers on cut-to-length shafting and machined

parts are generally 1/16 x 45°. Depending on your

requirements, any type of chamfering is available.

Please specify your preference at the time of order. Other Specifications

There are many other material considerations which may

need to be taken into account during the material

selection process other than those listed above. A few

of the less common ones include:

Sensitivity to electrical conductivity and/or magnetism

Should you have additional questions at any time,

Application Support

personnel are available to assist you with your inquiries. Please

Contact Us

directly for more information about other material and material options. ____________________

Return to: Last Page |

|||||||||||||||||||||||||||||||||||||

|

© Strongbar (UK) Ltd. 2008 |

|||||||||||||||||||||||||||||||||||||